Motivation

In the context of Industry 4.0 (I4.0), optimization of manufacturing and logistics in Greece and internationally is driven by the integration of advanced technologies such as automation, data analytics, artificial intelligence, and the Internet of Things (IoT). These innovations are transforming traditional processes by enhancing efficiency, reducing costs, and improving quality across supply chains and production systems. Efforts to modernize manufacturing and logistics in Greece align with broader European goals, as the EU promotes digital transformation to strengthen competitiveness and sustainability in the global market.

By embracing smart factories and warehouses, predictive maintenance, and optimized resource management, businesses across Europe and internationally are leveraging Industry 4.0 solutions to address challenges such as fluctuating demand, resource scarcity, and environmental concerns, fostering a more resilient and agile industrial landscape.

Furthermore, Greece has the prospects of becoming an international T&L center of world-wide importance, while Industry 4.0 is identified as an opportunity not to be missed. The pandemic and its effects amplify the importance of these targets. Based on the above, the Industry 4.0 and T&L sectors need powerful, end-to-end and modular, cost efficient and easily integrated solutions that will cater to the needs of manufacturing sites, logistics hubs / warehouses, and of end-to-end transport.

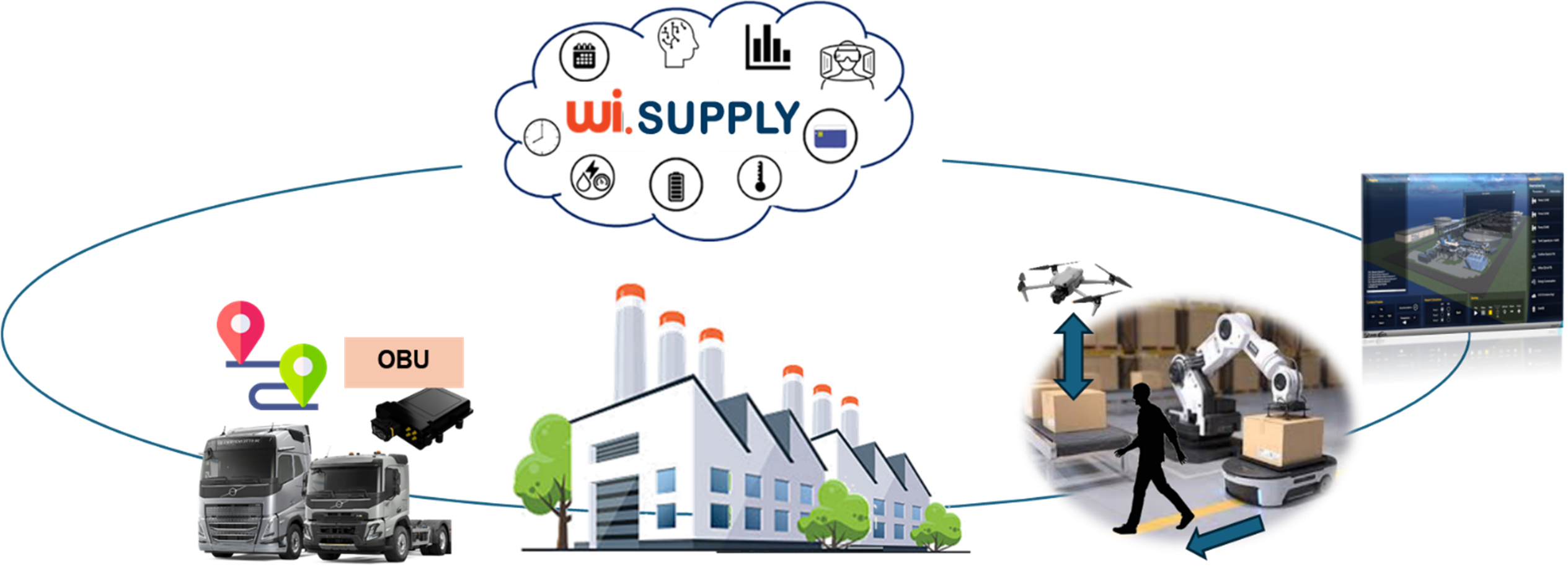

About wi.SUPPLY

wi.SUPPLY is the WINGS product that covers the requirements above and more. wi.SUPPLY enhances the automation and provides intelligence, to increase the efficiency and reduce costs in logistics warehouses, fleet monitoring and I4.0 sites.

Areas and Functionality

Logistics / Warehouses. In warehouses, WINGS focuses on capabilities and functions that improve operational efficiency including:

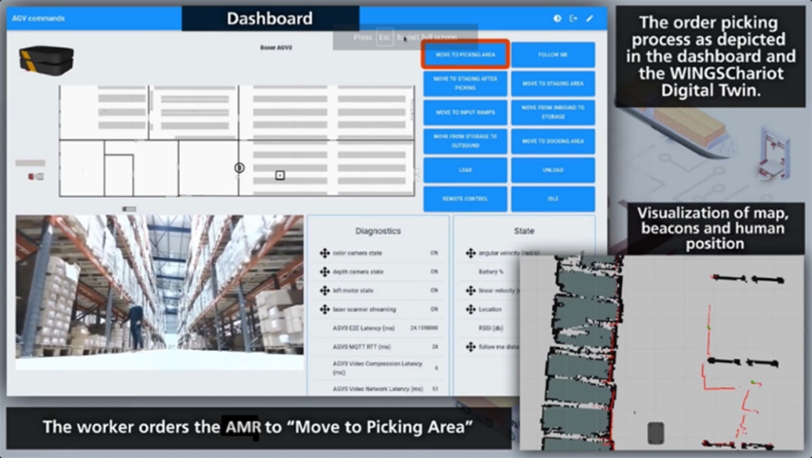

– Pallet transfer and autonomous transportation systems through unmanned movement of goods: These systems automate the movement of goods using AMRs, reducing manual labor and improving efficiency.

– Order formation and follow-me function: This feature enables robots or systems to dynamically assist in order picking and fulfillment, making logistics operations more flexible and responsive.

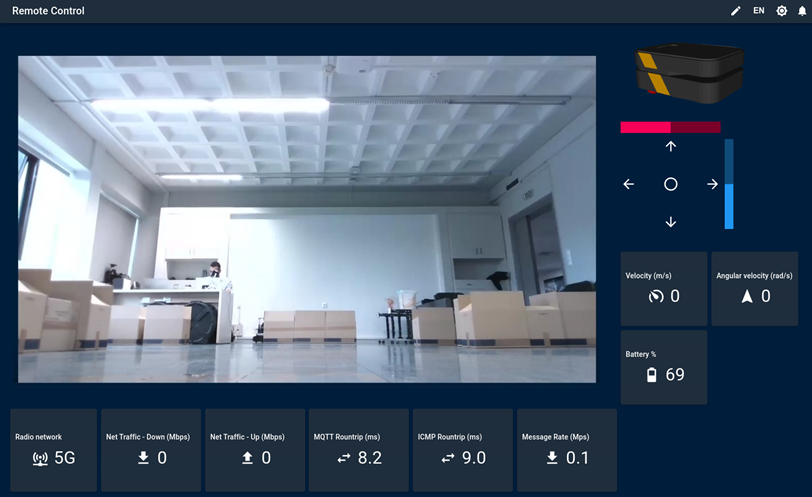

– Teleoperation: It enhances the ability to manage and control warehouse activities remotely, ensuring smooth and uninterrupted workflows.

– Storage Optimization and prediction of demand and storage: Advanced algorithms analyze demand patterns to optimize space utilization and ensure the right products are stored for future needs.

– Product protection / geofencing: Geofencing technology helps secure products by creating virtual boundaries, preventing unauthorized access or movement.

Logistics / On street / Corridors. The approach to freight transfer emphasizes optimized fleet monitoring and cooperation with infrastructure to ensure smooth and secure transfer of goods including:

– Optimized freight transfer: Efficient systems and strategies streamline the movement of freight via real-time tracking of vehicles ETA calculations and route optimization, are reducing delays and improving overall logistics performance.

– Driver behavior: Monitoring and analyzing driver actions help improve safety, fuel efficiency, and reduce operational costs.

– Vehicle maintenance: Proactive maintenance ensures vehicles operate reliably, minimizing downtime and extending their lifespan.

– ESG aspects: Incorporating Environmental, Social, and Governance principles promotes sustainable operations, reduces environmental impact, and ensures responsible business practices.

Manufacturing Plants / Factories. WINGS’ approach to factories involves continuous end-to-end monitoring and various optimizations aimed at improving quality, scheduling, and automation including:

– Quality optimization / raw: Ensures the quality of raw materials through testing and monitoring to meet production standards via image recognition and automated sorting of materials.

– Quality optimization / final product: Focuses on refining processes to deliver high-quality products that meet customer expectations and regulatory requirements.

– Scheduling production optimization: Improves production timelines by efficiently coordinating resources, processes, and workflows to minimize delays and maximize output.

– Resource optimization: Enhances the use of materials, energy, and labor to reduce waste and improve overall operational efficiency.

– Robotic applications: Utilizes robotics to automate tasks, improve precision, and increase productivity in manufacturing and production environments.

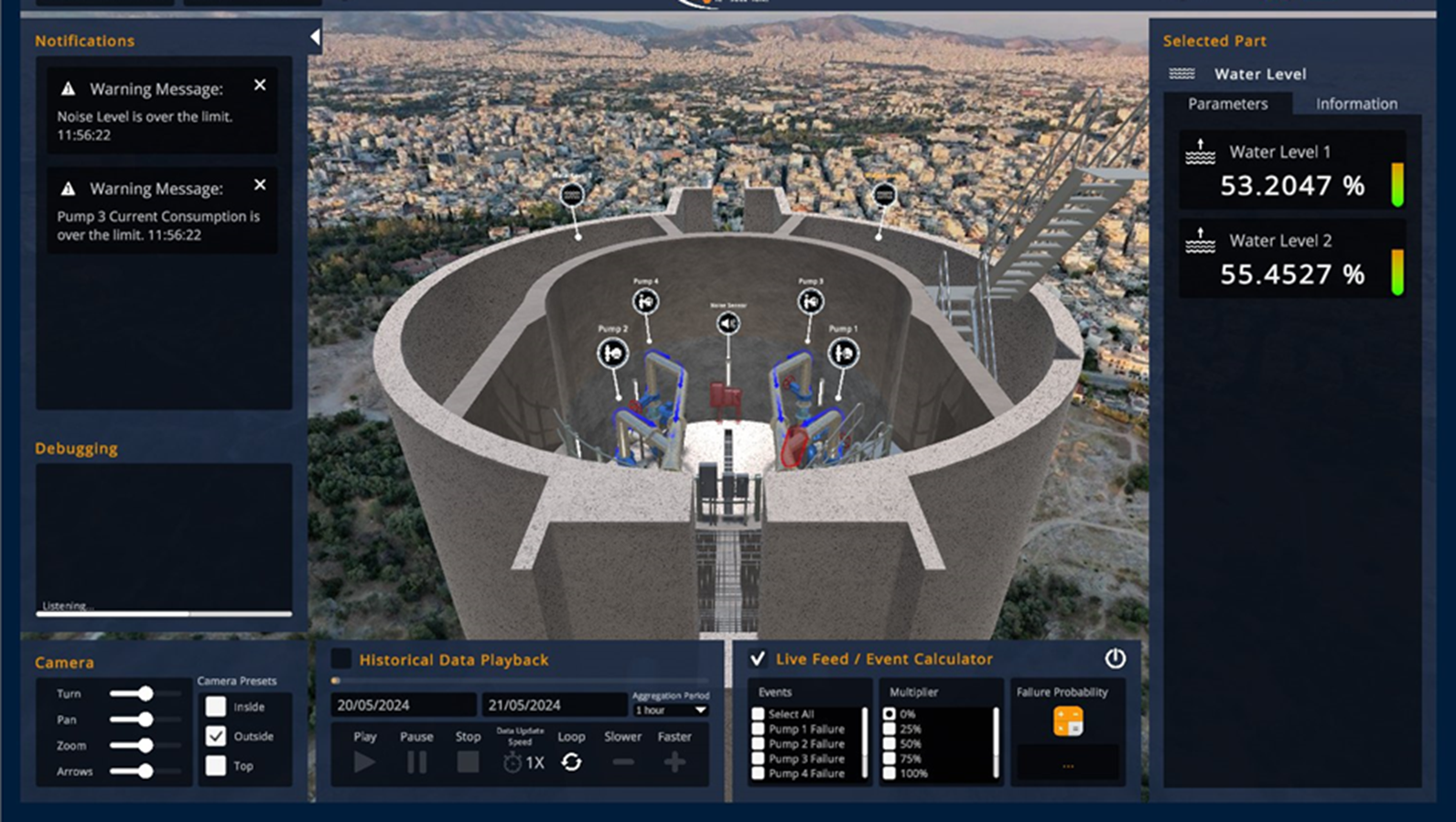

– Digital twins in manufacturing: Digital twins create virtual replicas of physical production systems, enabling real-time monitoring, simulation, and optimization of manufacturing operations.

Devices

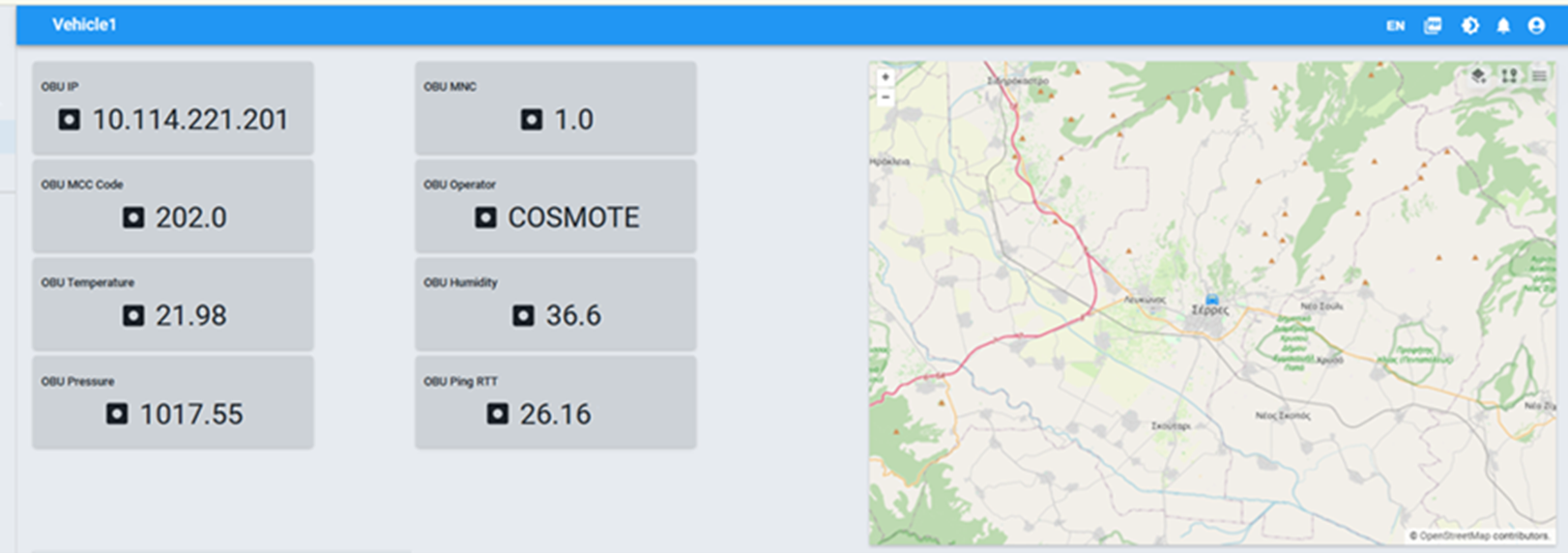

OBU: The vehicle’s on-board unit (OBU) is connected to every vehicle and is the intelligent hub for aggregating information from the car’s brain (Electronic Control Unit – ECU) and the included WINGS sensors (GPS, accelerometer etc.). It also includes the gateway with communication capabilities, for transmitting information and receiving instructions from/to the wi.SUPPLY platform and supports new generation cellular networks among others. This unit allows remote monitoring and control of vehicle and cargo status. The device is officially certified.

Autonomous Mobile Robots (AMRs) and drones: Within the warehouse and factories there are AMRs and drones that can enhance the automation and introduce intelligence in warehouses, in areas like the transportation: (a) of goods from the docking to the storage; (b) within the order management context; (c) from order management to shipping. Moreover, there are further devices, e.g., sensors, LIDARs etc., for boosting the efficiency of the operations.

Get a quote

Recent Articles